Why Invisible Quality Defines True Quality

When customers choose us, they are not just choosing an ergonomic chair, but a long-term guarantee of hassle-free quality assurance. Every effort we put into the hidden details will ultimately translate into tangible business value for our clients: lower after-sales costs, more stable user trust, and a stronger brand moat.

That’s why we confidently offer a 5-year warranty on every chair we produce — it is a testament to our absolute confidence in our product’s hidden quality, and a long-term commitment to our global partners.

Focusing on hidden quality details helps minimize chair malfunctions and reduces the need for repairs, product returns, and logistics costs.

A durable and comfortable product encourages repeat purchases from customers, boosting your brand’s reputation and market position.

Our stringent quality control ensures a trustworthy product, helping you establish a solid image as a reliable supplier in the industry.

Core Features & Craftsmanship Breakdown

Organize content into multiple columns to share useful information to your customers about your products, values...

Engineered Control System

10 years of R&D expertise with a dedicated Independent Chassis Workshop, ensuring 100% trial assembly and rigorous inspection. We integrate world-class German BOCK chassis in our flagship models. Specifically, the T9 utilizes Aviation-grade Fiberglass mechanisms, while the X6/X7/T9 feature professional Forward-Tilt functions.

Precise control reduces pressure on thighs and knees, improving circulation. Our line-controlled system allows for effortless, intuitive adjustments.

Class 4 Safety & Extreme Durability

We utilize Class 4 Gas Lifts from KR Samhongsa with 2.5mm wall thickness and 99.7% pure Nitrogen, treated with QPQ Nitriding for anti-corrosion.

Our reinforced bases support up to 1,360kg (1.2x BIFMA standard), ensuring a wobble-free experience for years.

Total peace of mind. Eliminates explosion risks and seat instability, supporting a maximum weight capacity of 200kg.

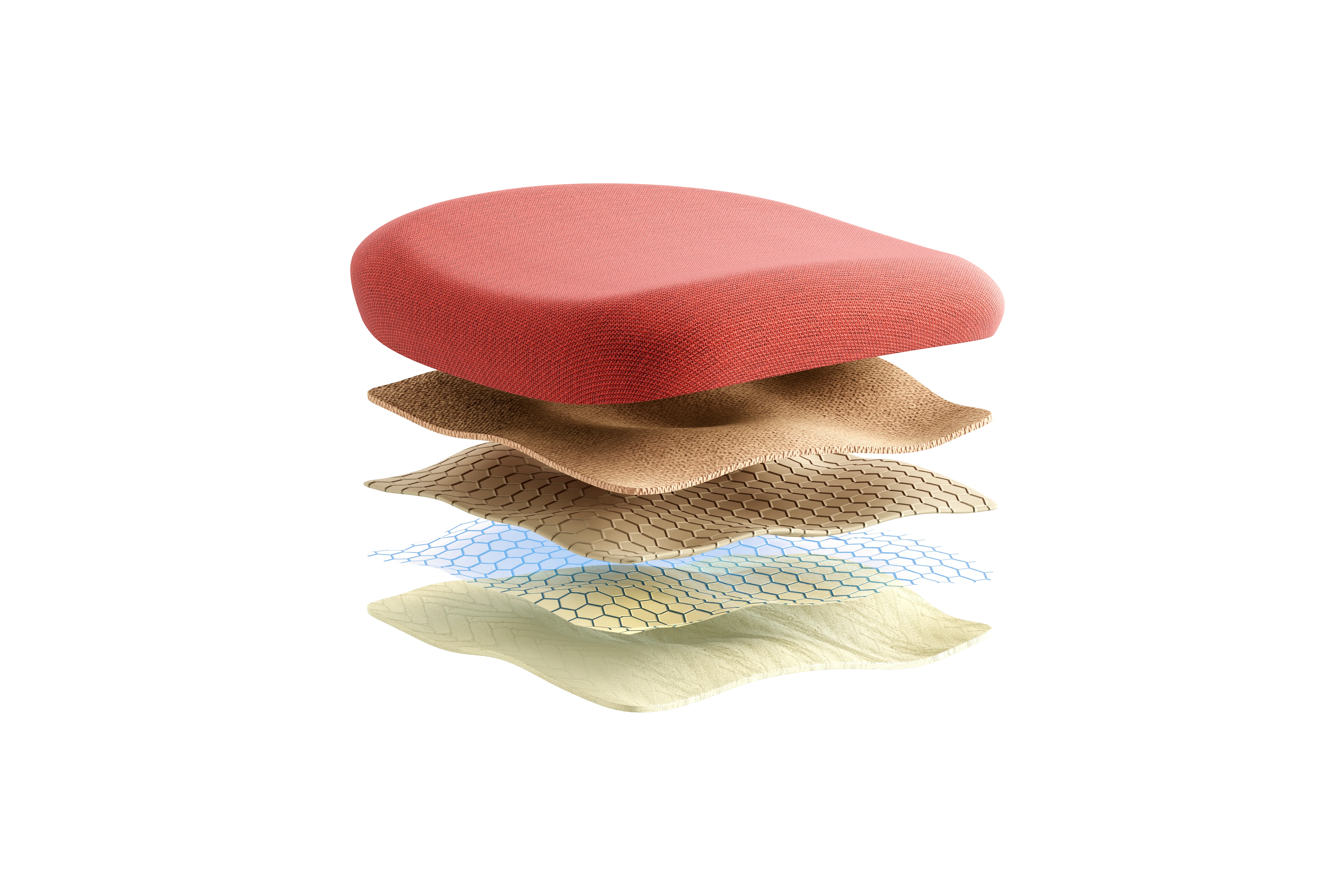

Molded Foam and INJECTION FORM Technology

The molded foam used in our chairs, similar to memory foam, provides superior comfort and support. This manufacturing process guarantees higher product quality and environmental advantages.

Zero-Formaldehyde "Eco-Injection"

Using advanced CNC high-temperature injection molding to fuse foam directly to the seat board.

Our process is 100% Glue-Free, ensuring an eco-friendly build.

No chemical odors and no foam sagging over time. It provides a healthier environment for professional workspaces.

Premium Structural Materials

Precision engineering using 33% Fiberglass + 67% Nylon blends. High-end models (X7, X6) feature an All-Aluminum Alloy frame (armrests, backrest connectors, and chassis).

Unlike standard plastic frames, our Aluminum Alloy & Fiberglass construction prevents deformation and breakage over a 5–10 year lifespan.

Maintains "as-new" structural tension even in heavy-duty commercial settings.

High-Performance Technical Fabrics

Development of custom mesh that is IPX6 Water-Resistant and GREENGUARD Certified.

Passes 100,000 Martindale rubs; it is oil-proof, water-resistant, and skin-friendly—ideal for airports, hospitals, and offices.

Easy to clean and resistant to aging. The mesh remains taut and supportive without losing its shape over years of use.

Trusted by Global Leaders

Beyond product, we prioritize partnership. These collaborations reflect our dedication to delivering high-quality, innovative results that drive real growth.